Lime producers in Great Britain have come together to launch an ambitious plan to accelerate decarbonisation and deliver ‘net negative’ carbon emissions by 2040.

Lime producers in Great Britain have come together to launch an ambitious plan to accelerate decarbonisation and deliver ‘net negative’ carbon emissions by 2040.

Spearheaded by the industry’s trade body MPA Lime, the Net Negative 2040 Roadmap explains how the sector can go beyond net zero a decade ahead of the UK’s overall 2050 target by deploying technologies such as fuel switching and carbon capture as well as recognition of lime’s natural carbon-absorbing properties.

The sector’s two main products – high calcium quicklime and dolomitic lime (dolime) – are extremely versatile and vital to numerous everyday essentials from the manufacture of metals, glass, plastics and building materials to the purification of drinking water, treatment of sewage, control of air pollution, animal welfare and production of many food staples including eggs, sugar and dairy products.

Used around the world for millennia, lime is made by heating quarried limestone or chalk to above 900 degrees centigrade to trigger a chemical reaction known as calcination. Around two thirds of the industry’s carbon dioxide emissions arise from calcination with most of the remainder resulting from fuel combustion.

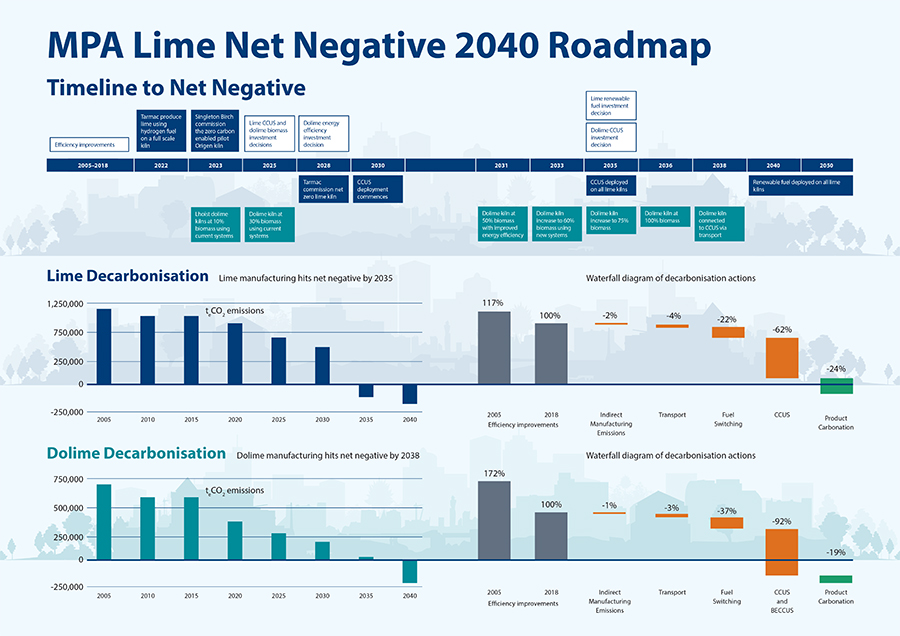

Since 2005, action and investment in the best available technology by British lime producers has already resulted in a reduction in absolute carbon emissions of around 25%. Now, the industry’s net negative roadmap identifies further technologies and infrastructure to fully decarbonise British lime production as well as outlining the enabling actions required by Government and other industries in the supply chain.

In addition, international research[1] confirms that around one third of the carbon dioxide from lime production is naturally reabsorbed from the atmosphere back into lime products – a process known as carbonation – but this is yet to be recognised in carbon accounting methodologies.

Combining the industry proposed developments with the enabling action by Government and the natural effects of carbonation, means the production of British lime could become net negative by 2040, and make a positive and ongoing contribution to addressing climate change.

Richard Stansfield, Chair of the MPA Lime management committee said: “The British lime and dolime industry has already achieved remarkable progress in both business commitment and tangible actions to decarbonise and play its part in tackling climate change. The publication of our Net Negative 2040 Roadmap is a milestone on the journey and serves to communicate, as well as incentivise, the changes that are essential for the future. The pace of change must accelerate and we are jointly committed to ensuring that it does. Importantly, we can’t achieve this alone. Reaching and exceeding net zero will also require some key enabling action by Government and others.”

The MPA Lime Net Negative 2040 Roadmap shows how lime production could be decarbonised by 2040 through the deployment of five key levers:

- Product carbonation – whereby exposure of lime products to the atmosphere can permanently absorb a third of the calcination related carbon emissions

- Fuel switching – away from fossil fuels to low or zero carbon alternatives like hydrogen or waste biomass could achieve a 22% carbon reduction for quicklime and 37% for dolime

- Carbon capture, Utilisation and Storage (CCUS) – a fundamental requirement that will account for more than half of emissions from lime production

- Reduction of the indirect emissions from electricity use

- Reduction of emissions from transport of materials.

Mike Haynes, Director of MPA Lime said: “Each lever will contribute to decarbonisation – many initiatives are happening already or will come on stream this decade – and in combination they will deliver a dramatic carbon reduction to reach zero by 2040. In addition, the combination of using biomass fuels with carbon capture and lime product carbonation will result in removal of 250,000 tonnes of atmospheric carbon dioxide every year, making the sector net negative overall. Other levers, especially indirect emissions and transportation, require broader collaboration and enabling action by Government and other industries.”

Ruth Herbert, Chief Executive of The Carbon Capture & Storage Association said:

“It’s fantastic to see such a vital industry as lime setting out its own net zero roadmap. The roadmap is clear that there is no option to decarbonise the lime industry without the installation of carbon capture utilisation and storage (CCUS).

“It’s clear that demand for CCUS from UK industries is very high – with this roadmap alone planning for all 5 sites to access CCUS clusters by 2038. This reinforces our message to the government that they need to urgently set out a national deployment plan for CCUS, indicating how and when sites like these can have access to CO2 infrastructure.”

Examples of enabling action by Government and other industries in the supply chain could include:

- Carbon accounting to ensure that net zero is not met by simply closing British manufacturing sites and importing goods instead

- Regulation that provides long-term visibility on decarbonisation policies and delivers cost competitive clean electricity

- Infrastructure that supplies green hydrogen to lime production sites and can transport captured carbon dioxide to storage or use

- Financial support that attracts investment to UK sites for the deployment of decarbonisation technologies

- and maintaining competitiveness to ensure British lime producers can continue to supply the UK and compete in international markets.

Mike Haynes continued: “Getting this enabling action right will allow the British lime industry to provide the whole of the UK and beyond, with net zero products that are essential to our everyday lives whilst removing more carbon dioxide from the atmosphere than it emits. The British lime industry is committed to addressing the challenges of climate change and we now have a credible roadmap to get us there.”

Download the MPA Lime Net Negative 2040 Roadmap

ENDS

MPA Lime Net Negative 2040 Roadmap: This ‘waterfall’ chart shows the contribution of each of the decarbonisation levers from historic baseline emissions in 2005 to a reference point in 2018, with each of the levers expressed as a percentage reduction of the 2018 reference. Some of the levers are happening now and are not yet accounted for (eg carbonation), some are relevant to early action (indirect emissions) and others can’t be deployed to their full potential right now due to the need for enabling action (fuel switching and CCUS). This is just one of the possible scenarios to deliver net zero production and net negative outcome.

CASE STUDY 1 - FUEL SWITCHING: A Government funded project in Britain led by MPA has demonstrated that hydrogen has excellent potential to replace natural gas for lime manufacture. The world first project provided greater understanding of key aspects including how to distribute energy across the kiln to ensure no impact on lime qualities. The results of the project will enable the sector to accelerate a switch to hydrogen when secure and cost effective supplies can be accessed. Alternatives to hydrogen include the use of biomethane and MPA Lime member Singleton Birch has partnered with Origen Power to develop a new kiln which uses oxy-fuel technology, fuelled with bio-methane from on-site production, as a route to zero carbon lime production. This new technology combines fuel switching with carbon capture and the first zero carbon lime is set to be produced from a pilot kiln in 2023.

CASE STUDY 2 - CARBON CAPTURE: MPA Lime members are already actively involved in the development of carbon capture use and storage (CCUS):

- Singleton Birch manufacture quicklime within the East Coast Cluster. The Zero Carbon Humber Cluster is a ‘Track 1’ cluster with ambitions to decarbonise the region by 2040. Singleton Birch aim to have kilns connected to CCUS by 2035 and to be running on hydrogen fuel by 2040.

- Tarmac and Lhoist both manufacture quicklime in the heart of Derbyshire, near Buxton. Five cement and lime plants across Derbyshire, Staffordshire and Cheshire, owned by Tarmac, Breedon, Lhoist and Aggregate Industries, together with Lostock Sustainable Energy Plant (LSEP) in Cheshire, have come together with Progressive Energy to form Peak Cluster. The project is closely associated with the North West Hynet cluster (another Track 1 cluster). The goal is for Peak Cluster to be operational by 2030 and in addition Tarmac and Lhoist should be running on hydrogen fuel by 2040.

- Lhoist also run the only dolime facility in the UK, and one of a handful in Europe. Reliant on solid fuels, early decarbonisation will come through efficiency gains and the use of biomass fuels. If this plant connects to a carbon capture cluster it will deliver ‘BECCUS’ – Bioenergy Carbon Capture, Use and Storage. By using biomass fuels and capturing the resulting emissions, dolime production will be actively removing atmospheric CO2.

About MPA Lime:

MPA Lime has three full members – Lhoist UK, Singleton Birch and Tarmac – which between them produce more than 1 million tonnes of industrial lime sold in the UK each year, as well as exporting specialist products overseas. In addition, there are three company Associate Members – British Sugar, Specialty Minerals and Tata Steel Europe – which produce industrial lime for their own product manufacturing. Each year the UK lime industry makes a GVA (gross value added) contribution to the economy of £55 million but is a critical supplier of products to a vast array of UK industry sectors that have an estimated combined turnover in excess of £500 billion[2].

There are two types of lime made in the UK – high calcium lime (quicklime, hydrated or slaked lime) and dolomitic lime (known as dolime) – and both are essential products for a vast array of uses:

- Manufacturing: iron and steel, as well as non-ferrous metals like aluminium, zinc and copper, and glass, paper, plastics, rubber and pharmaceuticals.

- Food and drink: purification of drinking water, production of sugar, dairy products and baking to fruit farming, fish farming and soil improvement.

- Sanitation: neutralisation of sewage and industrial effluents, absorption of gas emissions from power generation and animal welfare.

- Construction: mortars, renders and plasters, insulating building blocks, fire resistant boards, soil stabilisation in infrastructure, asphalt modification, and specialist heritage applications www.mpalime.org.

For further information visit www.mpalime.org.

About the Mineral Products Association:

The Mineral Products Association (MPA) is the trade association for the aggregates, asphalt, cement, concrete, dimension stone, lime, mortar and silica sand industries. With the merger of British Precast, and affiliation of the British Association of Reinforcement (BAR), the British Calcium Carbonate Federation, the Cement Admixtures Association (CAA), CONSTRUCT, Eurobitume, MPA Northern Ireland, MPA Scotland and the UK Quality Ash Association (UKQAA), it has a growing membership of 520 companies and is the sectoral voice for mineral products. MPA membership is made up of the vast majority of independent SME quarrying companies throughout the UK, as well as the 9 major international and global companies. It covers 100% of UK cement and lime production, 90% of GB aggregates production, 95% of asphalt and over 70% of ready-mixed concrete and precast concrete production. In 2018, the industry supplied £16 billion worth of materials and services to the Economy. It is also the largest supplier to the construction industry, which had annual output valued at £172 billion in 2018. Industry production represents the largest materials flow in the UK economy and is also one of the largest manufacturing sectors.

For media enquiries, contact Elizabeth Clements at: Elizabeth.Clements@mineralproducts.org